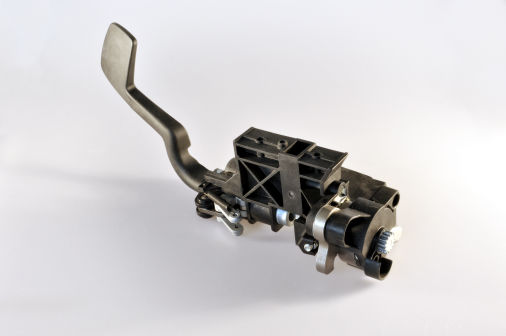

Industrial Components

SLT-IC provides an assembly service for industrial components. This could be manual assembly or

production in semi-automatic custom-made machines. We work with the customer to decide on the best process in which the product will be made. SLT-IC can be responsible for developing the production equipment, or conversely it can be provided by the customer. We work with several different materials such as plastics, rubber and metal. Working in accordance with LEAN principles help us to develop the company and better meet customer requirements on quality, delivery precision and price.

Together with our partner Anva Polytech we are producing rubber components in injection molding machines.

Our customers can be found in industries such as automotive, outdoor power equipment and furniture.